Automatic Oil Tank Dewatering and Desalter system with the ID-200h

Our Tank Dewatering is a breakthrough technology that ensures the highest accuracy, down to low ppm levels, effectively eliminating the loss of hydrocarbons in the water draw-off line.

Trusted by some of the best in the industry.

Precision Interface Detection

Explore the ID-200H’s advanced capabilities in delivering accurate oil-water interface detection.

Leading Control and Automation

Discover how the ID-200H enhances automated processes for efficient dewatering and desalting.

Durability in Diverse Conditions

Learn about the ID-200H’s durability and adaptability across diverse operational environments.

Stopping waste

The waste and cost of slop oil.

With crude oil under $100/bbl and poor oil and water interface/separation control, refineries accidentally dump crude oil and/or refined products into the wastewater treatment system regularly. The oil is not lost but is recovered in the wwts/api separator. However, it is no longer virgin crude oil or refined product – the lights have evaporated, and the product has been sheared and emulsified by pumps & contaminated with solids. In effect, it has been reduced to recovered slop oil. The ID200 is the perfect solution to automatic tank dewatering.

A typical refinery today will accidentally dump 0.5% to 1.0% of its total throughput to the water treatment systems because of poor interface/separation control. For a 100,000bpd refinery, this equals 500 to 1,000bpd of recovered slop oil.

Winner of Best Supplier Service at WWEM 2022

Sensor features

ID200h Series Enhanced Connectivity and Power Efficiency

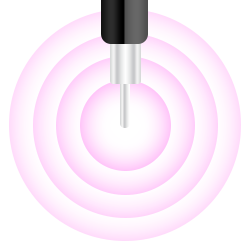

A high-frequency, low-power energy is broadcast.

The detection range is a 3″ sphere around the tip.

Some of the energy is absorbed by the medium surrounding the antenna.

The analogue signal is generated relative to the absorption rate.

Demo Video

Energy absorption technology

The Agar ID-200 Series Interface Detectors are a cornerstone in automatic tank dewatering and separation processes. These detectors, crafted from robust 316 stainless steel and available in specialized materials like duplex and hastalloy, are designed for precision in challenging environments. They excel in high-pressure scenarios up to 3000 PSI and can withstand a broad temperature range from- 40°F to 185°F (-40 °C to 85°C). The ID200h Series further enhances this lineup with its 2 Wire Loop Powered system and HART communication, ensuring efficient operation and seamless integration in advanced control systems. Ideal for various industrial applications, the ID-200 Series is a testament to innovation in automatic tank dewatering and liquid/liquid separation technology.

The ID-200 Series Interface Detector in action.

Dive into the world of precision process control with our exclusive photo gallery of the Agar ID-200 Series Interface Detectors. From the sleek stainless steel build to the advanced technological features, our gallery offers a closer look at what makes the ID-200 a leader in automatic tank dewatering and liquid separation processes. See why it’s the preferred choice for industry professionals.