Demonstrating the Automatic Tank Dewatering and Desalting Sensor

Trusted by some of the best in the industry.

Unique 4-phase technology

82% reduction in slop oil waste

Accurate Interface Control

Saving you millions

By installing ID-200 Interface Detectors, a US refinery reduced its total HC being dumped to the WWTS by 82% with better interface/separation control. An 82% reduction in SLOP OIL generated equals £1,990,424 per year in savings/additional profit. Not just for the first single year but continuing year after year.

Prevention is better than the cure.

The ID200h is the first and only interface control system to utilize this understanding of the oil/water interface as the basis for control. The system consists of a minimum of two or a maximum of four Agar energy absorption instruments: three designated for service in the vessel and one installed upstream of the unit in the crude feed line. In the System 3 control scheme, this sensor provide continuous 4 to 20 mA output signals proportional to the % water concentrations at their locations inside the desalter.

Demonstrating how the ID200 functions.

Installation of the ID200

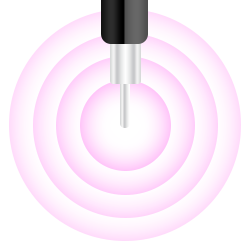

A high-frequency, low-power energy is broadcast.

The detection range is a 3″ sphere around the tip.

Some of the energy is absorbed by the medium surrounding the antenna.

The analogue signal is generated relative to the absorption rate.

Unique 4-phase system

What are the four methods of dewatering?

Phase 1

The first phase controls the brine outlet valve – using its ability to measure small amounts of oil in water to maintain a very high (and unstable) percentage of water several feet above the bottom of the vessel. This allows suspended oil in the water phase to separate, thus inhibiting oil undercarry as a primary control function. While sensor #1 establishes this lower limit for the emulsion layer, anything that floats on the water phase stops here.

Phase 2

Monitors the % water content from its position in the oil phase just below the lower grid. This provides real-time detection of the rate and extent of emulsion growth (which must, by sensor #1’s control, occur in the upward direction). Sensor #2’s monitoring function allows the operator to avoid downstream upsets by providing advanced warning of such growth and allows time to implement corrective measures to prevent grid loss (transformer “trip”).

Phase 3

It is an in-line monitor of the water content of the crude feed and is typically located upstream of the desalter (generally at or near the tank farm). This sensor provides advanced warning of wet/contaminated crude feed, which is necessary to avoid the upsets typically resulting from tank switching and the introduction of slop oil.

Phase 4

The fourth sensor monitors the condition of the water phase below the control sensor, alarming the presence of suspended oil that does not readily separate and threatens the condition of the brine effluent. This is of particular value when low-quality sources of wash water (e.g. stripped or straight sour water) are utilised that can upset the separation process and form stable oil-in-water mixtures (reverse emulsions). This is also used during mud-wash cycles.

Your questions answered about tank dewatering.

How can tanks be dewatered?

Oil tanks can be dewatered using several methods, but one of the most effective is interface detectors like the ID200. These devices precisely measure and control the separation of liquids, allowing for the efficient removal of water from various substances. Other methods include centrifugation, filtration, and using absorbent materials, each suitable for different types of tanks and contents.

What does a dewatering tank do?

A dewatering tank separates water from other materials, such as sludge, oil, or other industrial fluids. The primary function is to reduce the volume of the material by removing the water content, making the remaining substance easier to handle, process, or dispose of. This process is essential in many industries, including wastewater treatment, oil refining, and chemical processing.

What happens to dewatered sludge?

Dewatered sludge, the solid material left after water removal, can be processed in several ways. It is often treated further to reduce contaminants and then repurposed or disposed of safely. Common uses for treated sludge include agricultural fertilizers, landfill cover, or as a fuel source in incineration processes. The method of disposal or repurposing depends on the sludge’s composition and level of treatment.

What is the most effective dewatering system?

The effectiveness of a dewatering system depends on the application’s specific requirements. However, systems incorporating advanced interface detectors like the ID200 are often considered the most effective. These systems offer precise control, high efficiency, and adaptability to various industrial needs. Other effective systems include belt filter presses, centrifuges, and screw presses, each having its advantages depending on the material being processed and the desired outcome.

All great relationships start with a conversation.

To contact us, or to request a callback, simply use this form and we will promptly get back to you.

To celebrate the smart features of our ID-200h, we will be entering the details of everyone who enquiries into a prize draw for the Amazon Echo Show 10.

A list of past winners can be found here.